INTEGRATION OF TECHNOLOGIES FOR WASTE RECOVERY

Most of the sanitary landfills in Latin America present serious problems of clogging and saturation, short useful life, each time they need to affect more land to expand them, generating even more contamination with the consequent public health problems in surrounding areas. For all this, it is necessary to implement TECHNOLOGICAL MIGRATION PROGRAMS, leaving behind sanitary landfills to implement Environmental Technology Parks, which produce clean energy from waste.

The Recovery technologies that we bring as integrators to Latin America offer a solution for the total elimination of Urban Solid Waste (MSW), Hazardous Hospital and Industrial, Oil and Coal; through its conversion into Synthetic Gas (Clean SynGas) using them as FNCER – NON-CONVENTIONAL SOURCE OF RENEWABLE ENERGY.

The Bio and Thermo valorization products comply with the most demanding world standards: policies, laws and procedures required by international, state and government agencies that protect the environment.

We carry out comprehensive support in the processes of technological updating, choosing the most appropriate process according to the type of waste, financing facilities through multilateral funds, for public and private actors.

Remox has achieved approval by a Latin American government of the first Integral Waste Recovery project through the figure of Public-Private Association for the Department of Risaralda in Colombia.

INTEGRATED TECHNOLOGIES

Our technologies are based on the Biomethanization of biodegradable materials and Plasma Gasification of inorganic material, it constitutes the most efficient alternative due to its high energy performance in a clean way, without polluting residues and with almost zero emissions of polluting gases due to the high temperatures that eliminate environmental risks.

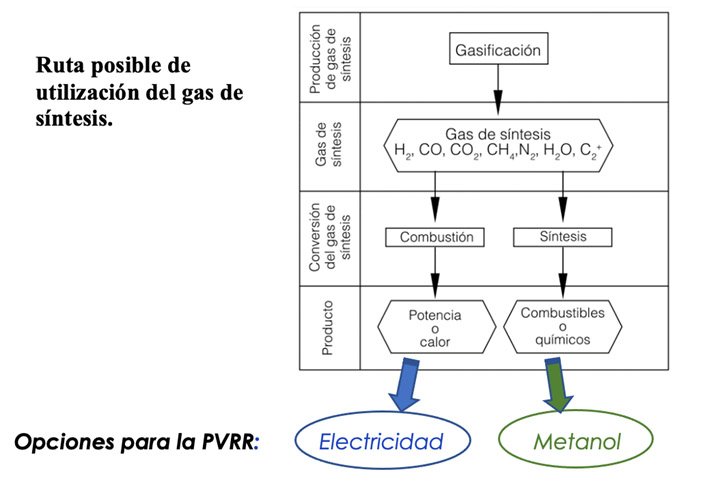

The basic product of the process is Clean Synthetic Gas (SynGas) and Biogas, from which Electricity and/or other By-products are produced such as: Methanol, Ethanol, Ethylene, Hydrogen, Nitrogen, Ammonia, Gasoline, Naphtha, Synthetic Waxes ; complying with the most demanding global standards: policies, laws and procedures required by international, state and government agencies that protect the environment.

PRODUCTS FROM A WASTE RECOVERY PLANT – PVR

INTEGRATED PROCESS FOR USW VALUATION

Classification and Separation

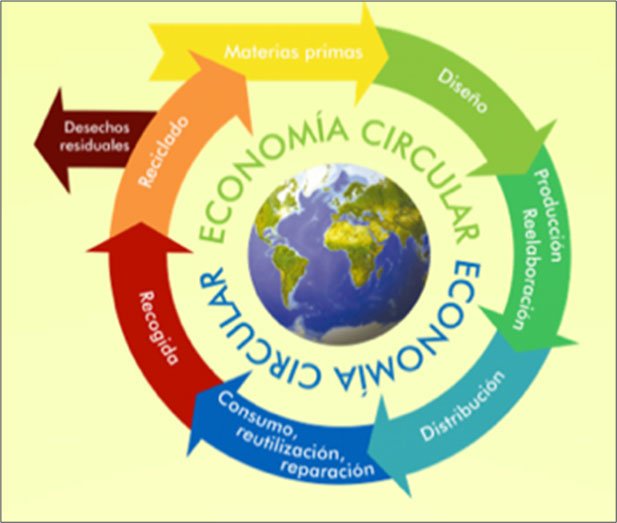

Mechanical process of discrimination and separation of recyclable waste to be reintegrated into the circular economy cycle, and the rest to biological and thermal recovery. Recyclers from the area are integrated into this process.

Bio-Safe Feeding System for RESPEL

Mechanical feeding process for hospital hazardous waste, through independent feeding and with biosafety systems in the process. This process is carried out with personnel trained for the particular handling of this type of waste.

Recycling

Reinsertion of waste in the productive cycle of the circular economy, as new products or raw material for new processes. Products susceptible to commercialization from the mechanical separation classification process are recycled.

It integrates with personal recyclers in the area.

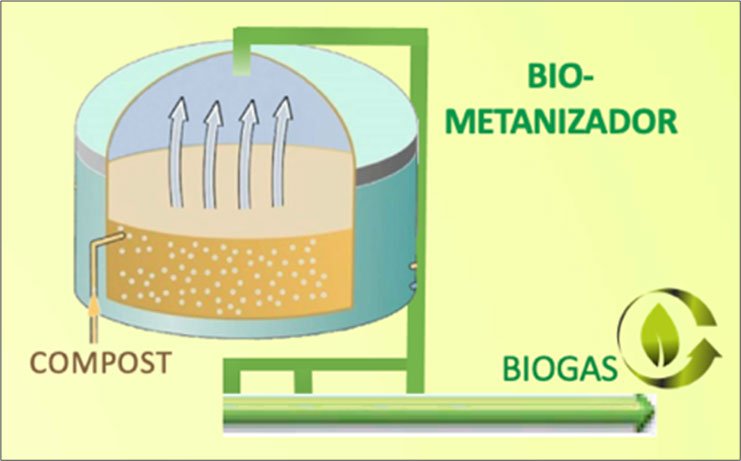

Biomethanization

Biological process in high-performance reactors that generate biogas from biodegradable organic waste. The products are a compost useful as fertilizer for crops and Biogas (methane CH4) that is integrated into the electric power generation process.

Gasification

Thermochemical process in high energy plasma reactor. The high temperatures of the process (>5,000ºC), produce a thermal efficiency greater than 90% that maximizes the energy obtained from matter, and converts it into synthetic gas (syngas) that is used to generate electrical energy.

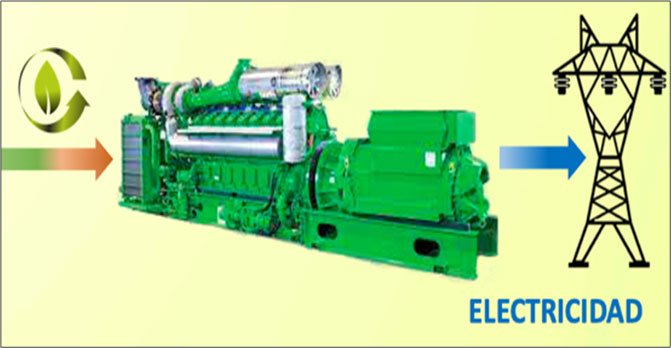

Electric Power Generation

Electrical energy is produced in engines or turbines that use biogas and syngas as fuel, and eventually steam turbines that use the heat generated in thermal processes through combined cycle -IGCC-. It is also possible to produce Methanol, Naphtha or Hydrogen, from the syngas.

Methanol Production

Using catalysts, Syngas (or synthesis gas) is transformed, achieving cost-effective and energy-efficient production to synthesize chemicals such as ammonia, methanol, and hydrogen, as well as for fuel cells, gas processing, and various gas processes. to liquid (GTL), coal to liquid (CTL) and biomass to liquid (BTL).

Sewage treatment

The wastewater treatment process reduces the biological and biochemical oxygen demand of the liquid waste from the different processes of the plant.

Air Treatment

The project includes a system for treating air contaminated by odors from the waste before it is processed.

Facilities for environmental education and technology transfer

The project includes educational and training infrastructure to facilitate the transfer of knowledge on integrated technologies and on environmental issues in general.

Installation of services for recyclers staff

As a physical component of the support program for recyclers, an infrastructure of sanitary services, a reception center, toilet areas and a meeting, food and rest area are provided to support their organization and work efficiency.

RECOVERY OF OIL WASTE AND COAL:

Oil Clears:

The lees and drilling muds are waste with a high caloric content that can be used. They are highly polluting waste, Gasifying them produces double benefits: Energetic and Environmental.

Convert Fuel Oil to Syngas:

Heavy Fuel Oil or Combustóleo, can be transformed into Syngas to generate electrical energy, taking advantage of it with greater thermal and electrical efficiency, and avoiding the environmental and health impact that occurs in combustion.

Convert Syngas to Methanol or Hydrogen:

From Fuel Oil, RSU and other residues, it is possible to produce methanol, hydrogen, naphtha, gasoline and other chemical fuels.

Convert Coal to Gas and Liquid Fuels:

Coal can be converted into gases and liquids through gasification processes, these are called synthetic fuels that pollute less air than when burned by combustion.

COAL plasma gasification increases by more than 60% the energy obtained by thermal combustion.

WHERE ARE WE GOING…

With manufacturers and suppliers in the USA, Spain, Italy and Germany; REMOX integrates technologies and advances the development of projects -GPAE- «Gasification by High Energy Plasma» in several countries of Latin America and the Caribbean: Colombia, Ecuador, Mexico, Panama, Aruba, Paraguay, Argentina and the Dominican Republic.

THE FUTURE …

As the generation of energy from Urban Solid Residues USW serves as the financing base for this technological change, the way we see the problem of garbage in the world will be transformed from being a problem to one of the greatest opportunities. evolution towards a self-sustaining society.

TYPICAL TREATMENT PLANT AND INTEGRAL VALORIZATION OF MSW

THE GROUP OF COMPANIES «REMOX INGENIERÍA SAS» and «REMOX ENERGY CO.», develops the implementation of the GPAE Integrated Gasification solution for public and private entities, such as:

OFFICIAL TERRITORIAL ENTITIES RESPONSIBLE FOR THE PUBLIC TOILET SERVICE.

CONCESSIONARIES AND OPERATORS OF SANITARY LANDFILLS IN LATIN AMERICA.

DANGEROUS SOLID WASTE COLLECTION AND DISPOSAL DEALERS (BIOLOGICAL AND INDUSTRIAL).

OIL COMPANIES

THERMO-GENERATORS OF ELECTRICITY FROM FUEL OIL

SMALL, MEDIUM AND LARGE COAL MINING.